Our Services

- Post lease servicing, minimising downtime for lessors and maximising leasee utilisation

- Keeping your engine compliant and within legislation

- Full video gas path Borescopes

- Compressor blade blending

- In-Situ engine blade repair

- Eddy Current Testing

- Dye Penetrant Testing

- Ultrasonic Testing

- Visual Inspection

- Acid Etch preparation

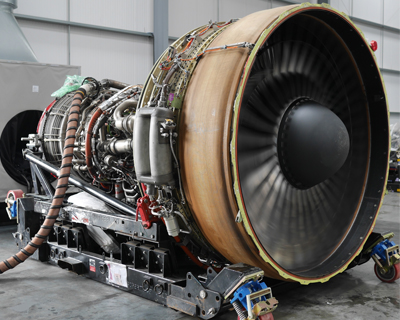

- Complete QEC/EBU build

- QEC/EBU strip and recertification if required

- Thrust Rating changes

- Fire Detection system alterations

- High quality detailed photo reports of overall engine condition

- Bespoke onsite preservation facility providing 365 day preservation

- Off site preservation response team

- A mobile team of Certifying Engineers to support AOG & Planned Maintenance worldwide.

- Capabilities to carry out repairs and servicing to OEM standards using genuine OEM spares

- Bespoke equipment for engine handling including 2 forklift trucks with specialist forks and a 20 tonne overhead crane

- HMRC Customs Warehouse approval allowing parts and engines to be held in a bonded environment

- CAA regulated agent approval enabling rapid dispatch of 'known' status goods

- Excellent working relationship with Jan de Rijk who are European specialists in road transportation for the aerospace industry

- Capacity for storage of up to 120 engines

- Periodic Storage Inspections

- Wrapping of Engines for long term storage in accordance with regulations